Production Consistency!

LOW COST AUTOMATED VISUAL INPECTION

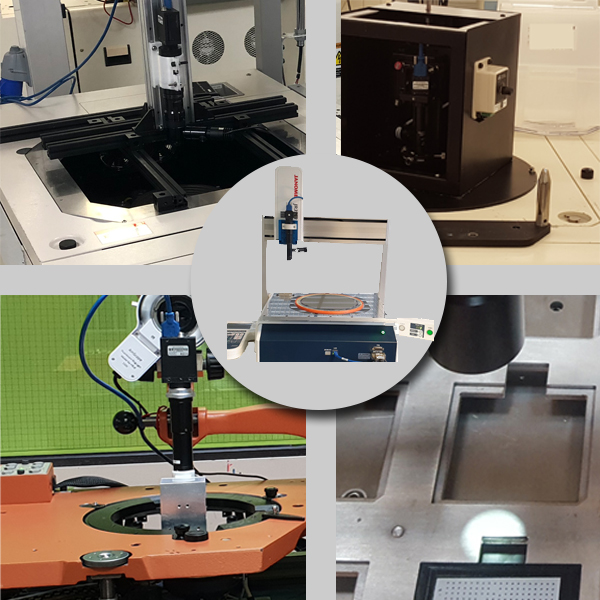

The most flexible platform available. Wafers – Diced Wafers – Singulated Die – Modules – More!

Multiple Options: Software only : Semi-Auto : Fully Auto

Rapid ROI

Focus on essential needs keeps costs to a minimum – with a rapid Return on Investment.

Automation

Fitting easily into your global production needs, improving productivity. Semi to fully-Auto.

Consistent

Reduce operator interpretation. Get accurate and reviewable results for your production and quality needs.

Let us show you with an online demo

Integrate into your test floor

Combine or enhance your electrical wafer map data. Pass-fail-review criteria are easily established. Review tools ensure efficient monitoring and archive retrieval – even remotely.

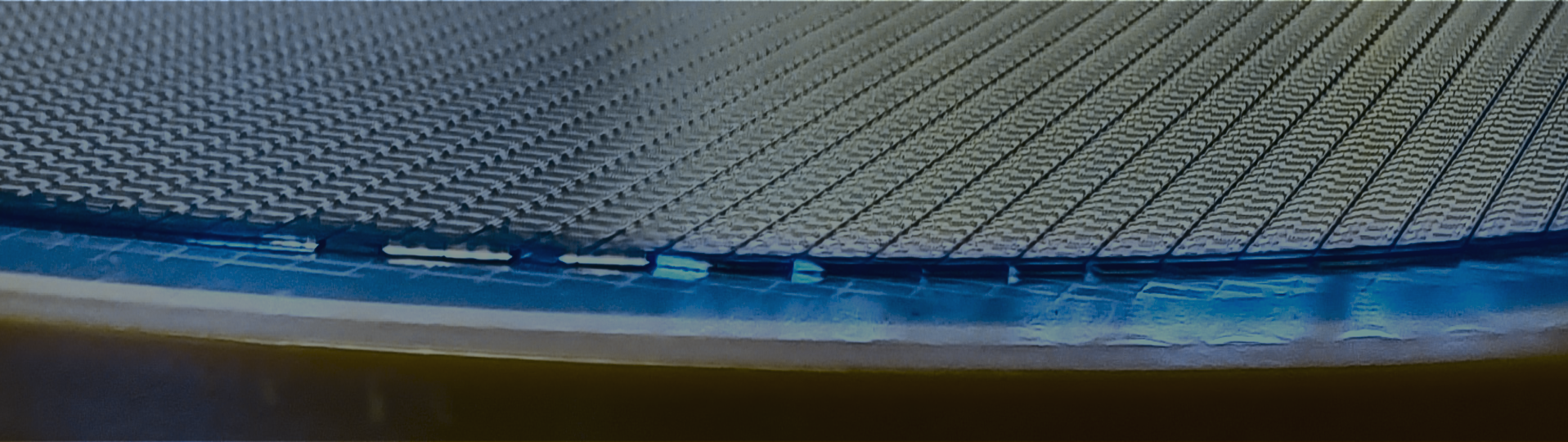

Typical Defects

Dirt – Debris – Scratches – Probe mark, Ball analysis – Process defects – Plus many more…..

Instantly identify defect trends or misprocessing.

Incoming & Outgoing Quality Assurance

“Point Of Interest” sub-routines automate and record details at specific locations. Incoming or outgoing specifications are met ensuring quality.

Spot Checks and archive for quality monitoring

You will now have a record for archive and review purposes – you decide what you keep and for how long!

Multi-camera lens options ensure your needs are met in terms of resolution and field size..

Review or re-process results from anywhere

Our network and remote architecture means you don’t have to be in front of a machine to review or reprocess results – you can be in the comfort of your desk or even working from home.

“The ability to pass/fail and review modes production fails from anywhere brings new capability to our QA control”

“Using the systems as a production filter, means we manually review less product, speeding everything up in production”

“Operators are happier, as their time is now spent on analysis rather than spotting and counting defects on mainly good / passed die”